Outdoor Distribution Board (Feeder Pillar Box) – Weatherproof Power Distribution Unit

The Outdoor Distribution Board / Feeder Pillar Box is a robust, weatherproof electrical enclosure designed for safe and reliable distribution of power in outdoor environments. It acts as a central point for connecting incoming and outgoing feeders, providing protection, control, and isolation for underground or overhead power distribution networks.

Built with corrosion-resistant materials and equipped with high-quality switchgear components (MCBs, MCCBs, fuse units, isolators, and busbars), the Feeder Pillar Box ensures uninterrupted power delivery in harsh weather conditions. It is commonly installed in public utilities, street-lighting systems, industrial campuses, and commercial outdoor setups.

Power Control Centre (PCC) – Centralized Power Distribution & Protection Panel

The Power Control Centre (PCC) is a high-capacity electrical panel designed to control, manage, and distribute power safely across industrial and commercial installations. PCC panels serve as the main power distribution point within a facility, handling large electrical loads and providing precise protection through advanced switchgear components.

Equipped with Air Circuit Breakers (ACBs), MCCBs, metering systems, busbars, and monitoring devices, PCC panels ensure stable, safe, and efficient power distribution. Built with robust enclosures and high-fault-level ratings, they are ideal for continuous heavy-duty power applications.

Motor Control Centre (MCC) – Centralized Motor Control & Power Management System

A Motor Control Centre (MCC) is a centralized panel system designed to control, protect, and manage multiple electric motors in industrial and commercial environments.

Built with high-quality switchgear components, MCC panels integrate motor starters, overload relays, contactors, circuit breakers, and monitoring devices in a single enclosure. They ensure reliable motor operation, enhanced safety, simplified maintenance, and smooth process control.

MCCs are ideal for facilities with numerous motors operating simultaneously, such as manufacturing plants, HVAC systems, pumping stations, and processing units.

Final Distribution Board (FDB) – Circuit-Level Electrical Distribution Panel

The Final Distribution Board (FDB) is a compact electrical panel designed to deliver power from Sub Distribution Boards (SDBs) to end-use circuits such as lighting, sockets, appliances, and small equipment.

Built to ensure safe, controlled, and organized power distribution at the final delivery point, FDBs incorporate protective devices like MCBs, RCCBs, and miniature busbars. These boards play a crucial role in preventing electrical hazards by isolating individual circuits and providing overload and short-circuit protection.

Ideal for homes, offices, and commercial spaces, they ensure reliable and efficient power distribution to the final electrical loads.

Sub Distribution Board (SDB) – Secondary Power Distribution Panel

The Sub Distribution Board (SDB) is a secondary electrical panel designed to receive power from the Main Distribution Board (MDB) and safely distribute it to various localized circuits. Built with high-quality protective devices and durable enclosures, SDBs ensure safe load management, circuit isolation, and efficient power routing across residential, commercial, and industrial facilities.

Engineered to handle multiple outgoing feeders, these boards improve electrical safety, protect equipment from overload/short-circuit, and offer easy accessibility for maintenance.

Main Distribution Board (MDB) for Power Control & Electrical Distribution

The Main Distribution Board (MDB) is the central electrical panel responsible for receiving incoming power from the utility or transformer and distributing it to various sub-distribution boards, circuits, and loads. Built with high-quality switchgear components, it ensures safe, reliable, and efficient power distribution across an entire facility.

Engineered to handle high current ratings, MDBs include main incomer breakers, busbars, protective devices, metering, and outgoing feeders. These boards are designed with robust enclosures, proper ventilation, and advanced safety mechanisms to ensure stable operation even under heavy electrical demand.

Suitable for industrial plants, commercial complexes, data centers, and residential buildings, MDBs play a vital role in electrical safety, overload protection, and system management.

High-Torque Gear Motors for Industrial Power Transmission

Gear Motors combine an electric motor with a gearbox to provide optimized speed and torque output for various mechanical operations. These motors are engineered for high efficiency, durability, and smooth performance under continuous or intermittent load conditions.

Available in multiple gear configurations—including helical, worm, planetary, and bevel—gear motors support applications requiring slow rotational speeds with high torque. Their compact design, robust housing, and optional mounting styles make them ideal for automation, conveyors, machinery, and material-handling systems.

Designed for long service life, gear motors utilize hardened gears, high-quality lubrication, precision bearings, and efficient cooling systems to ensure consistent performance in industrial environments.

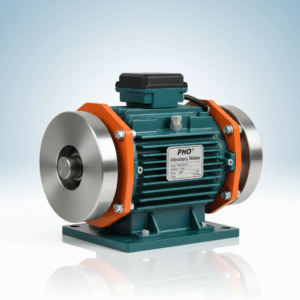

High-Performance Vibratory Motors for Industrial Vibration Equipment

Vibratory Motors are compact, powerful electric motors equipped with adjustable eccentric weights on both shaft ends to produce controlled vibration. These motors are widely used in industries for vibrating screens, feeders, conveyors, compaction tables, hoppers, and material flow systems.

Engineered with rugged housings, high-grade bearings, and precision-balanced rotors, vibratory motors deliver consistent vibration strength and long-term reliability. Their adjustable centrifugal force allows fine-tuning based on application requirements. Available in multiple mounting styles, duty ratings, and vibration outputs, they are suitable for heavy-duty industrial operations.

Cooling Tower Motors for HVAC and Industrial Cooling Systems

Cooling Tower Motors are specially engineered to handle the demanding conditions of cooling tower applications. These motors operate continuously in environments exposed to moisture, humidity, and fluctuating temperatures. Built with high-grade insulation, corrosion-resistant materials, and enhanced ventilation systems, they deliver consistent performance even in harsh outdoor conditions.

They are designed for direct-drive or belt-driven cooling tower fans and ensure energy-efficient airflow for industrial, commercial, and HVAC cooling systems. With robust bearings, high torque, and low vibration, these motors provide long service life and minimal maintenance.