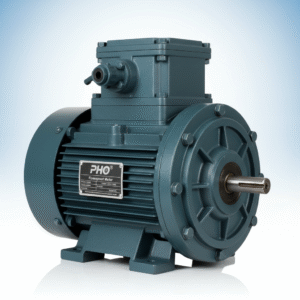

Flameproof Motors for Hazardous Industrial Environments

Flameproof motors are engineered to operate in explosive or hazardous environments where flammable gases, dust, or vapors are present. These motors feature a rugged, enclosed construction that can withstand internal explosions without allowing flame propagation to the surrounding atmosphere. Known for their durability, high efficiency, and reliability, flameproof motors are widely used across oil & gas, chemical plants, mining, refineries, pharmaceuticals, paint industries, and other high-risk zones. They are built to meet international safety standards and provide dependable performance even in the harshest conditions.

Flameproof motors designed to operate safely in hazardous areas with explosive gases, dust, or vapors, ensuring reliable performance and maximum safety.

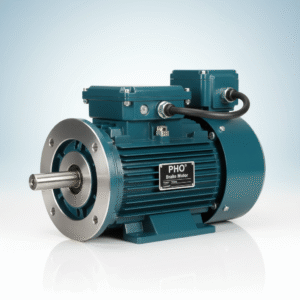

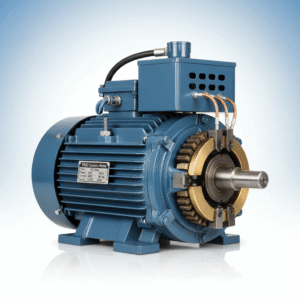

Brake Motors – Precision Stopping AC Motors for Industrial Applications

Brake Motors are specially designed AC motors equipped with an integrated electromagnetic or DC brake system that provides instant stopping, controlled holding, and improved safety for industrial machinery. These motors combine reliable electrical performance with high braking accuracy, making them ideal for applications requiring frequent start-stop operations, quick stopping, or load holding at any position. Built with robust construction, high-quality brakes, and thermal-resistant insulation, Brake Motors ensure smooth, safe, and maintenance-friendly operation in demanding environments.

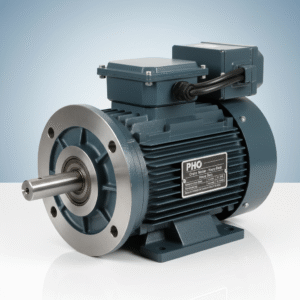

Crane Duty Motors – Heavy-Duty AC Motors for Lifting & Material Handling

Crane Duty Motors are specially designed AC motors built to handle intermittent duty cycles, frequent starts/stops, and high starting torque demands in lifting and material handling applications. These motors are engineered for robust performance, delivering reliable operation under varying load conditions found in cranes, hoists, winches, and industrial lifting systems. With reinforced mechanical strength, high thermal capacity, and durable insulation, Crane Duty Motors ensure superior performance and long service life in harsh industrial environments.

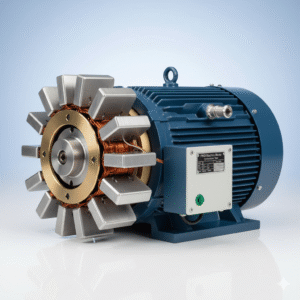

Synchronous Motor – Constant Speed Industrial AC Motor

A Synchronous Motor is a high-precision AC motor designed to operate at a constant speed, regardless of load variations. Unlike induction motors, it runs in perfect synchronism with the supply frequency, making it ideal for applications requiring accurate speed control and consistent performance. These motors use either permanent magnets or an excited rotor winding and are widely used in industrial automation, power factor correction, robotics, and high-precision machinery. Built for reliability and efficiency, Synchronous Motors deliver stable operation even under demanding industrial conditions.

Slip Ring Induction Motor – High-Torque Industrial AC Motor

A Slip Ring Induction Motor is a specialized AC motor designed for applications requiring high starting torque, smooth acceleration, and adjustable speed control. Unlike squirrel cage motors, it uses a wound rotor connected to external resistances through slip rings, allowing fine-tuning of torque and speed during startup. This makes it ideal for heavy-duty machinery, high-inertia loads, and industrial processes that demand controlled motor performance. Slip Ring Induction Motors are robust, reliable, and built to operate under demanding conditions.

Squirrel Cage Induction Motor – High-Efficiency Industrial AC Motor

A Squirrel Cage Induction Motor is a rugged, reliable, and widely used AC motor designed for continuous industrial operation. Its rotor has a unique "squirrel cage" structure made of conductive bars and end rings, enabling smooth torque delivery, low maintenance, and long service life. Known for its durability, high efficiency, and simple construction, this motor is ideal for heavy-duty applications requiring consistent performance and minimal downtime.

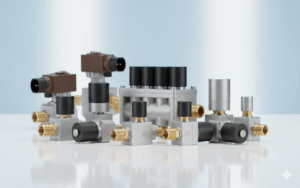

Solenoid Valves – Electrically Controlled Flow Automation Valves

Solenoid Valves are electromechanically operated valves used to control the flow of liquids or gases in industrial and commercial systems. Activated by an electric current through a solenoid coil, these valves provide rapid switching, high reliability, and precise flow control. They are widely used in automation systems, pneumatic and hydraulic circuits, water treatment, HVAC applications, and process industries. Designed with robust materials and high-quality coils, Solenoid Valves ensure long-lasting performance even in demanding environments.

Safety Relief Valve – Overpressure Protection for Industrial Systems

A Safety Relief Valve is a critical protection device designed to automatically release excess pressure from pipelines, tanks, boilers, and process equipment. It prevents damage, system failure, and potential hazards caused by overpressure conditions. Engineered with precision spring-loaded or pilot-operated mechanisms, these valves ensure maximum safety, reliability, and consistent performance across demanding industrial applications. Safety Relief Valves are widely used in steam, gas, air, oil, and chemical processing systems.

Strainers – Industrial Pipeline Protection Filters

Strainers are essential industrial flow-control components used to filter out debris, particles, and contaminants from pipelines. Installed upstream of valves, pumps, meters, and mechanical equipment, strainers protect critical components and ensure smooth and efficient system operation. Built with high-strength metallic bodies and precision-engineered mesh screens, they offer reliable performance in high-pressure and high-temperature environments across various industries.