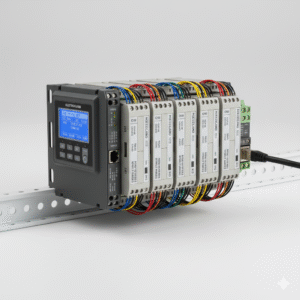

PLC (Programmable Logic Controller)

A PLC (Programmable Logic Controller) is a rugged industrial digital computer used for automation of electromechanical processes such as control of machinery on factory assembly lines, industrial equipment, and process control systems. PLCs are highly reliable, designed for harsh industrial environments, and allow easy programming, monitoring, and modification of automated processes. They form the backbone of industrial automation and control systems.

- Description

Description

Product Range / Variants

-

Compact / Micro PLCs

-

Modular PLCs

-

High-Performance / Advanced PLCs

-

Rack-Mounted PLCs

-

Ethernet / Network-Enabled PLCs

-

PLC with Analog and Digital I/O Modules

-

Safety PLCs

-

Specialized PLCs for HVAC, Water Treatment, or Manufacturing

Key Features

-

Reliable and rugged design for industrial environments

-

Programmable using Ladder Logic, Function Block, or Structured Text

-

Supports digital and analog input/output modules

-

Real-time monitoring and control

-

Communication protocols: Modbus, Profibus, Ethernet/IP, CANopen, etc.

-

Expandable with additional I/O and communication modules

-

High-speed processing for complex automation tasks

-

Compact and modular design for flexible installation

Technical Specifications

-

CPU Processing Speed: 0.1 μs – 1 ms per instruction (model dependent)

-

Input / Output Types: Digital (24VDC/230VAC), Analog (0–10V, 4–20mA)

-

Number of I/O: 8 – 1024+ (depending on PLC model)

-

Power Supply: 24V DC, 110V AC, 230V AC (depending on model)

-

Operating Temperature: -20°C to +60°C

-

Memory: 128 KB – 16 MB or more (program & data memory)

-

Communication: RS-232/RS-485, Ethernet, Modbus, Profibus, CANopen

-

Standards Compliance: IEC 61131-3, UL 508, CE

Applications

-

Industrial automation and machinery control

-

Process control in chemical, food, and beverage industries

-

Motor and conveyor control systems

-

HVAC and building automation

-

Water treatment and wastewater management

-

Renewable energy system automation

-

Packaging and assembly lines

-

Monitoring and control in power plants and substations

Benefits

-

Provides reliable, real-time control of industrial processes

-

Reduces manual intervention and human error

-

Scalable and flexible for small to large automation systems

-

Supports complex logic and sequential control

-

Easy to integrate with HMI, SCADA, and other automation devices

-

Rugged design ensures long operational life in harsh environments

-

Enables remote monitoring, diagnostics, and predictive maintenance

Material Grades / Build Options

-

Housing: Flame-retardant thermoset plastic or metal enclosure

-

CPU & Modules: High-performance industrial-grade semiconductors

-

I/O Modules: Digital, Analog, High-Speed Counters, Communication Interfaces

-

Mounting Options: DIN Rail, Panel Mount, Rack-Mount

-

Power Supply: 24V DC, 110V AC, 230V AC

-

Communication Ports: Ethernet, Serial (RS-232 / RS-485), Fieldbus Protocols

PLC (Programmable Logic Controller)

WE OFFER

Industrial-Grade Quality

We supply certified, durable, and performance-tested industrial products built to meet demanding work environments and safety standards.

Customized Fabrication

Our in-house fabrication team designs and delivers tailor-made steel structures, assemblies, and components as per client requirements.

On-Time Delivery

Reliable and timely dispatch across India with secure packaging and logistics support for all bulk and custom orders.

Expert Support

Get personalized assistance, technical advice, and after-sales support from our experienced industrial solutions team.

Adkrons Exims – Where Innovation Meets Industrial Strength

Adkrons Exims is a leading supplier of world-class industrial equipment, safety solutions, electrical components, and engineered fabrication products. Our focus remains on delivering precision, durability, and consistent performance to help industries operate safely and efficiently. From workshops to large manufacturing units, we are committed to providing reliable products and unmatched customer support.

Reviews

There are no reviews yet.